Get In touch

available from 10:00 – 19:00

Address: Svanevej 57, DK-4970 Rødbyhavn

E-Mail: info@dry-ice-dk.com

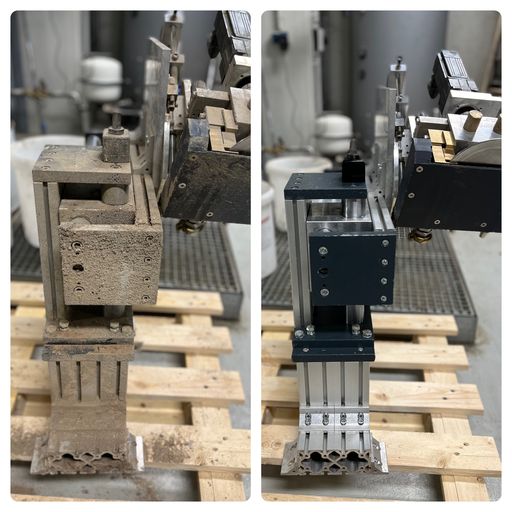

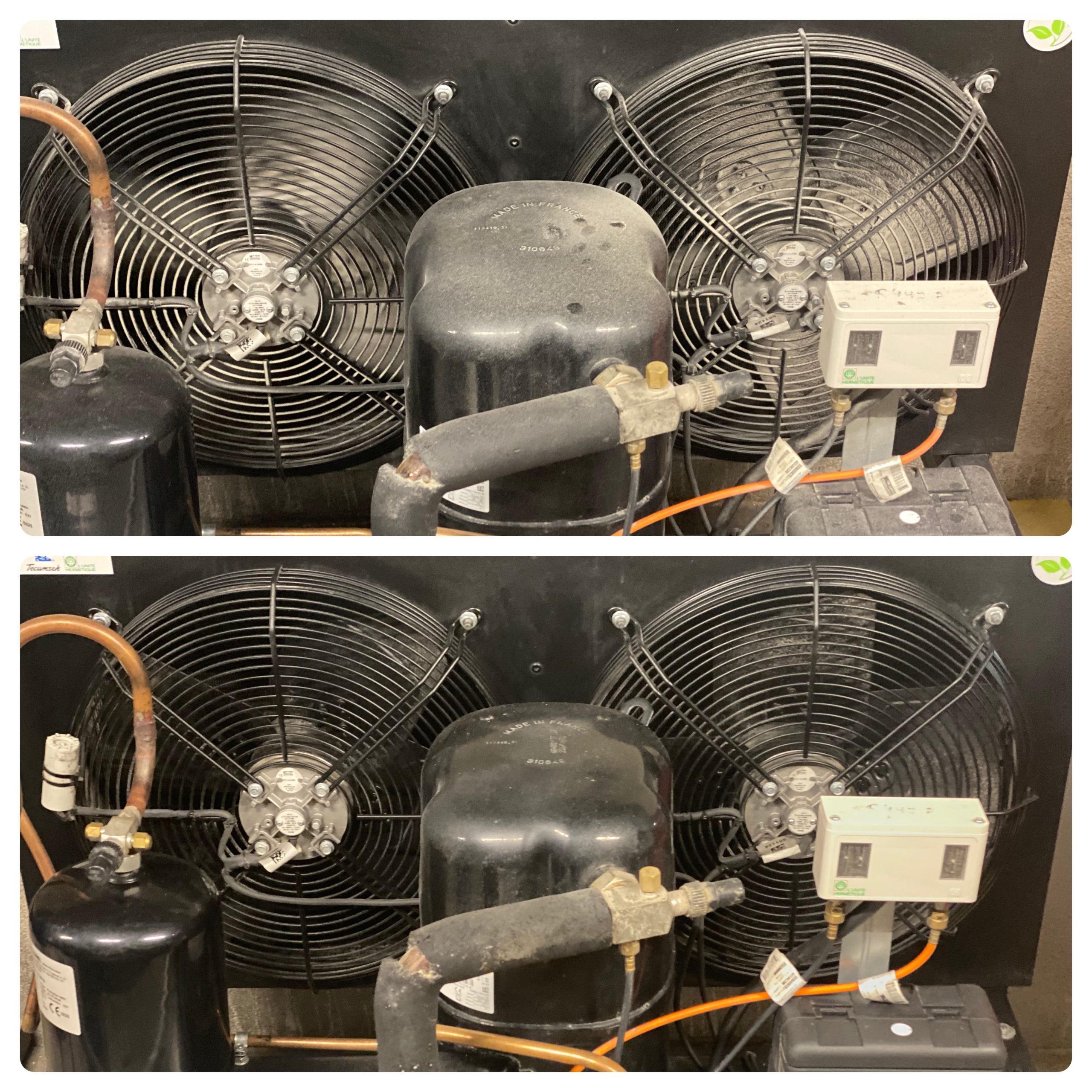

Your expert in dry ice cleaning. When it comes to thorough and effective cleaning of machines, equipment, buildings, and much more, dry ice blasting is a proven method that offers numerous advantages. We specialize in this innovative cleaning technology and provide tailored solutions for cleaning your equipment and facilities. Discover how we can help you bring your equipment back to its shine, while working environmentally friendly and cost-efficiently

Dry Ice Danmark APS is a leading provider of dry ice cleaning services in Denmark. We specialize in cleaning industrial equipment, but we also offer our services to other sectors, including automotive, food processing, and construction. Our innovative cleaning technology uses only snow dust to remove even the toughest contaminants without leaving any residue.

Our dry ice blasting process is completely eco-friendly, making it a sustainable solution for businesses looking to reduce their environmental impact. Unlike traditional cleaning methods that use harsh chemicals, our method is non-toxic and non-abrasive, which means it is safe for both people and equipment.

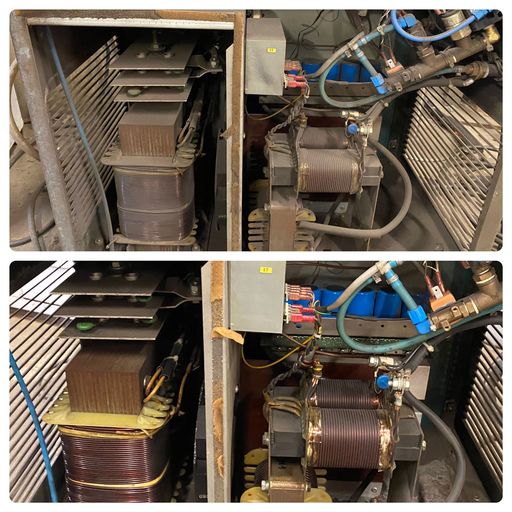

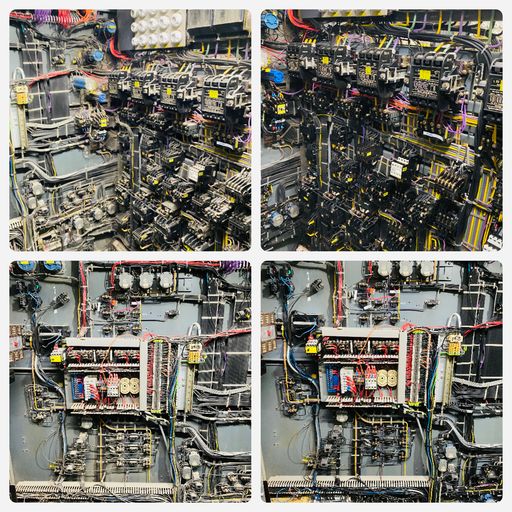

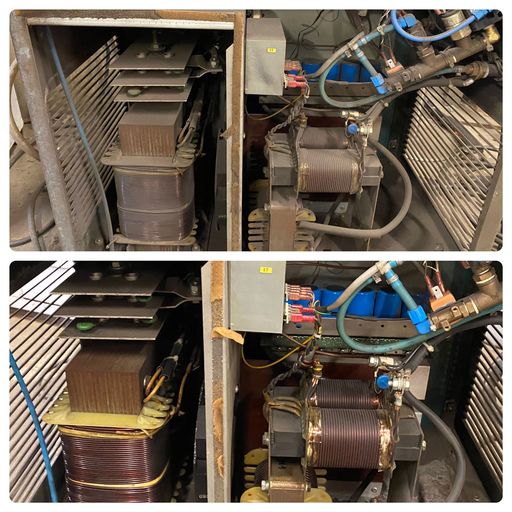

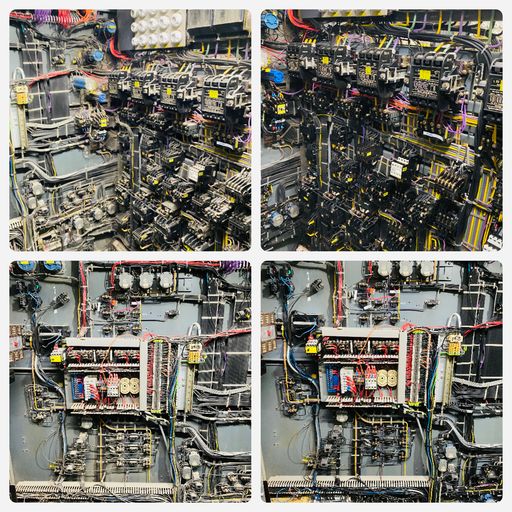

Dry Ice Danmark APS highly recommends the use of snow blasting for the proper cleaning of electronic components in machinery and equipment. Control cabinets, circuit boards, control elements, and electric motors are all prone to dust and dirt during the production process, which can compromise their efficiency and lifespan.

However, traditional cleaning methods that use water or chemical cleaning agents are not suitable for cleaning electronic components as they may cause damage due to moisture or chemical residues.

This is where snow blasting comes in – it is a completely dry cleaning method that uses sublimation to remove dirt and contaminants from sensitive electronic components without causing damage.

The experts at Dry Ice Danmark APS are passionate about providing their customers with the highest-quality snow blasting cleaning services to ensure that their electronic components are properly cleaned and maintained for optimal performance and longevity.

In addition to being a safe and effective cleaning method for electronics, snow blasting is also an eco-friendly solution. It does not use any chemicals or solvents that can harm the environment or pose health risks to workers. Instead, it utilizes dry ice pellets, which are made from reclaimed CO2 gas, to blast away dirt and contaminants.

At Dry Ice Danmark APS, we are dedicated to delivering exceptional snow blasting services for the cleaning of electronic components in machinery and equipment. Our team of experts has years of experience and knowledge in the industry, and we use state-of-the-art equipment and techniques to ensure that your components are properly cleaned and maintained.

So, if you want to ensure that your electronic components are cleaned properly and safely, look no further than Dry Ice Danmark APS. Contact us today to learn more about our snow blasting cleaning services and how we can help you achieve optimal performance and longevity for your electronic components.

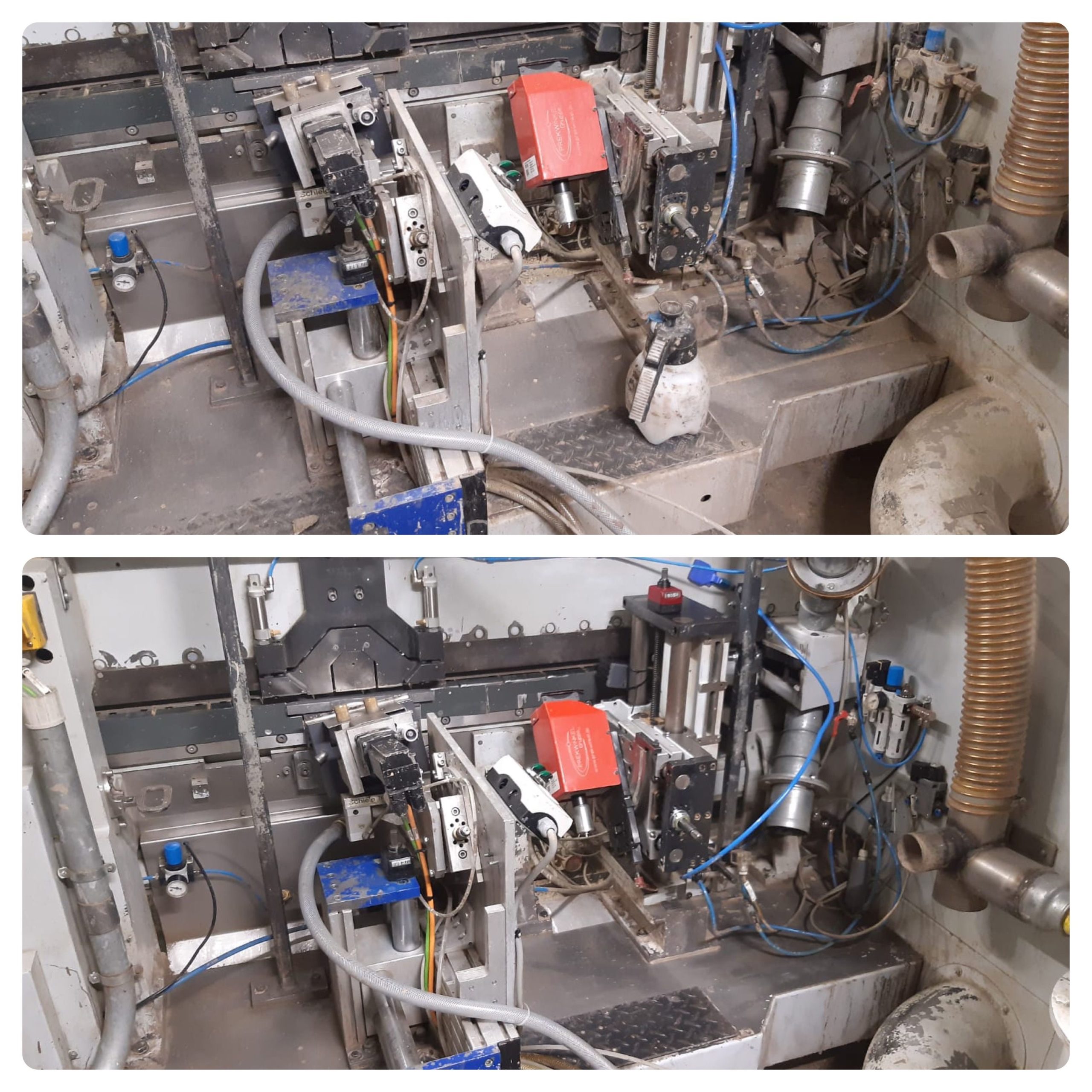

Our dry ice blasting method is effective in removing a wide range of contaminants, including grease and oil, paint residues, emissions, algae, rust, printer ink, graffiti, sealant residues, rubber, resin, bitumen, fire residues, wood stains, binders, lime, stickers, gum, adhesives, mortar, food residues, moss, protein residues, soot, dirt, silicone, starch, grape residue, release agents, undercoatings, encrustations, wax, cellulose, and cement.

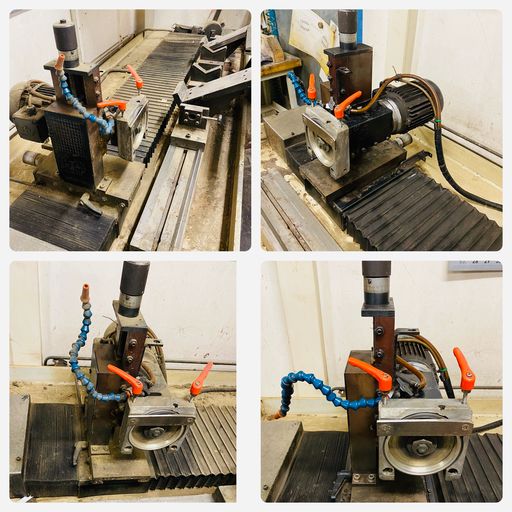

We understand that each industry has its unique cleaning needs, and that’s why we offer customized solutions that meet your specific requirements. Our team of experienced technicians has the knowledge and expertise to tackle any cleaning challenge, no matter how complex it may be. We work closely with our clients to develop tailored cleaning plans that deliver optimal results while minimizing downtime.

We use the latest dry ice cleaning equipment, which is designed to meet the highest safety and quality standards. Our equipment is regularly maintained and updated to ensure maximum efficiency and reliability. We pride ourselves on our ability to deliver high-quality services at competitive prices.

At Dry Ice Danmark APS, we are committed to providing our clients with the best possible CO2 blasting solutions. Whether you need to clean industrial equipment or remove graffiti from a building, we have the expertise and technology to get the job done quickly and efficiently. Contact us today to learn more about our services and how we can help you achieve your cleaning goals.

Frequently Asked Questions

We’ve compiled some of the most frequently asked questions about our dry ice cleaning service. If you have any additional questions, please don’t hesitate to contact us.

The process of cleaning that we use is called snow blasting, also known as dry ice blasting. In this process, we use only snow dust as the cleaning medium, as opposed to dry ice pellets that may be used in other processes. Snow dust is directed onto the surface to be cleaned using a stream of compressed air. When the snow dust hits the surface, it sublimates (changes directly from a solid to a gas), removing dirt and contaminants. Snow blasting is an effective, environmentally friendly, and gentle method of cleaning various surfaces.

Yes, snow dust cleaning, also known as dry ice blasting or ice blasting, is generally considered safe. It is a non-toxic and non-abrasive cleaning method that uses snow dust to remove dirt, grime, and other contaminants from surfaces. The process of snow dust cleaning creates a sublimation effect, which is the conversion of solid dry ice pellets into gas. This sublimation effect causes the pellets to disappear and leaves no residue, making snow dust cleaning an environmentally friendly cleaning solution.

Compared to other cleaning methods, snow dust cleaning is relatively safe as it does not involve the use of harsh chemicals or solvents that may pose health risks to workers or damage surfaces. It is also a dry cleaning method, which eliminates the risk of water damage or electrical hazards.

Overall, when performed correctly by trained professionals, snow dust cleaning is a safe and effective cleaning solution for a wide range of applications.

Dry ice cleaning offers several advantages over traditional cleaning methods. Here are some of the key differences:

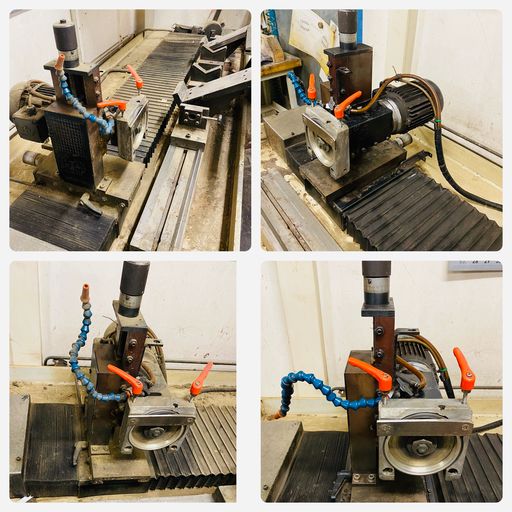

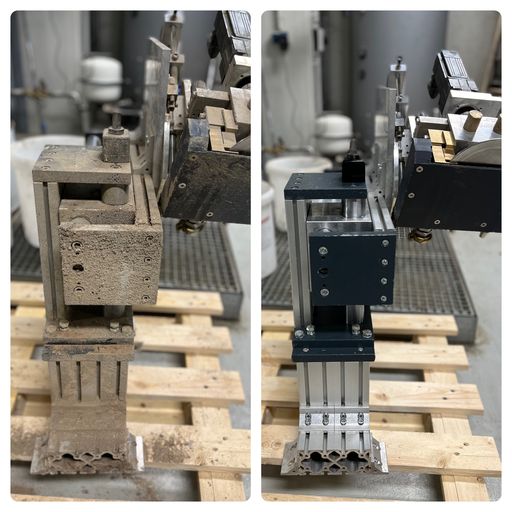

Efficiency: Carbon dioxide cleaning can often clean surfaces more quickly and thoroughly than traditional cleaning methods. The dry ice pellets used in the process can penetrate small crevices and hard-to-reach areas, removing dirt and contaminants that might be missed by other methods.

Non-abrasive: Unlike many traditional cleaning methods that rely on harsh chemicals or abrasive materials, dry ice cleaning is a non-abrasive and non-toxic cleaning method. It does not leave any chemical residue or secondary waste, and it is safe for use on delicate surfaces, such as electronics or food processing equipment.

Environmentally friendly: Dry ice cleaning is an environmentally friendly cleaning method, as it does not produce any secondary waste or harmful chemicals. The solid carbon dioxide used in the process is a byproduct of other industrial processes and is readily available.

Cost-effective: While dry ice cleaning may initially be more expensive than traditional cleaning methods, it can save money in the long run by reducing downtime and increasing equipment lifespan. It can also eliminate the need for costly and time-consuming disassembly and reassembly of machinery.

Versatility: Dry ice cleaning can be used on a wide range of surfaces and materials, including metal, plastic, rubber, and wood. It is also effective at removing a variety of contaminants, such as oil, grease, paint, and mold.

Overall, dry ice cleaning offers several advantages over traditional cleaning methods, making it a popular choice for industrial and commercial cleaning applications.

Dry ice cleaning is a versatile cleaning method that can be used in many different industries. Here are some of the industries that commonly use dry ice cleaning:

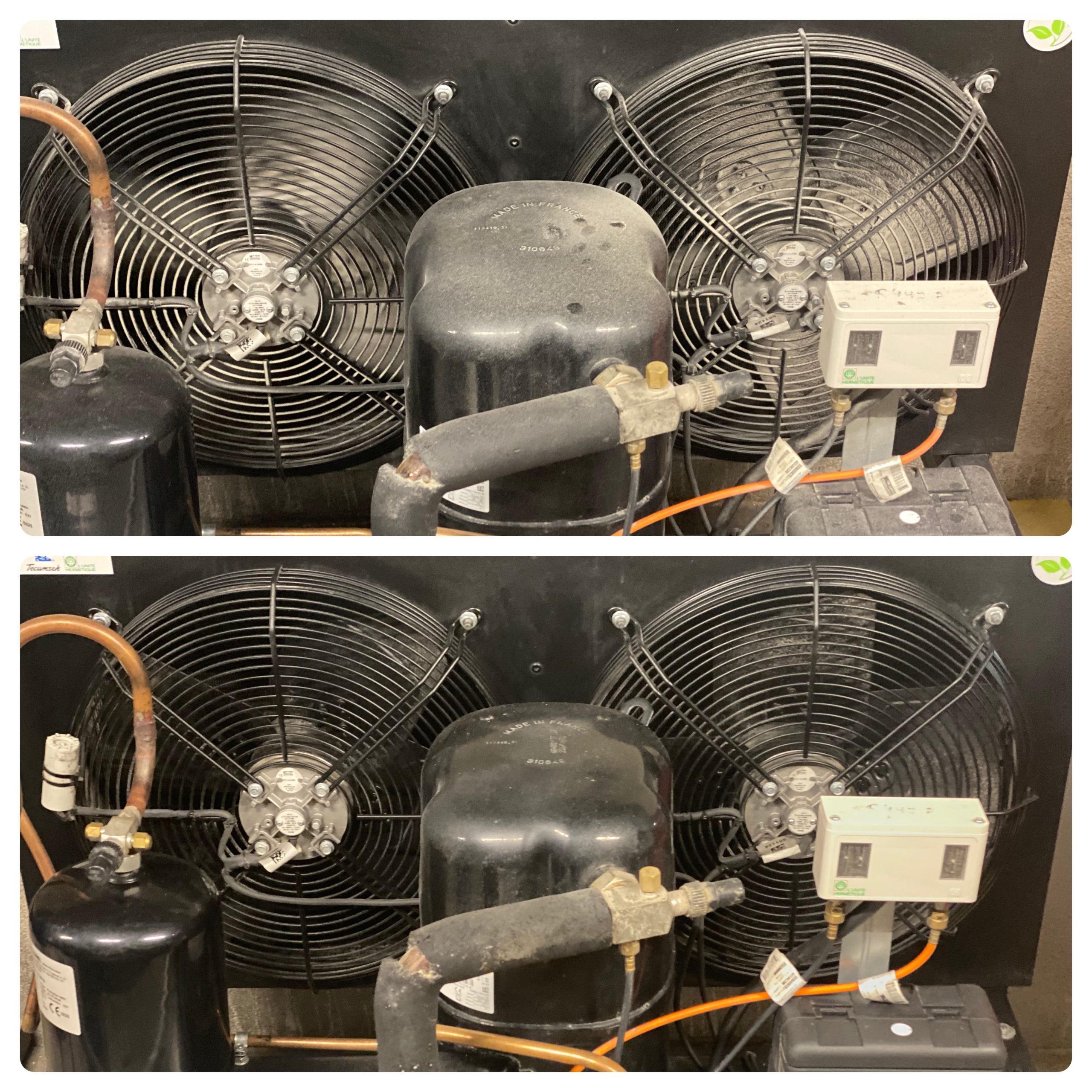

Food Processing: Snow debris blasting is an ideal method for cleaning food processing equipment and machinery, as it is non-toxic, non-abrasive, and does not leave any chemical residue. It can effectively remove contaminants such as bacteria, mold, and food particles.

Automotive: Snow powder blasting is used in the automotive industry to clean engine components, wheels, and other parts without damaging delicate surfaces or leaving any residue. It is also used for removing paint and adhesive residues from vehicles.

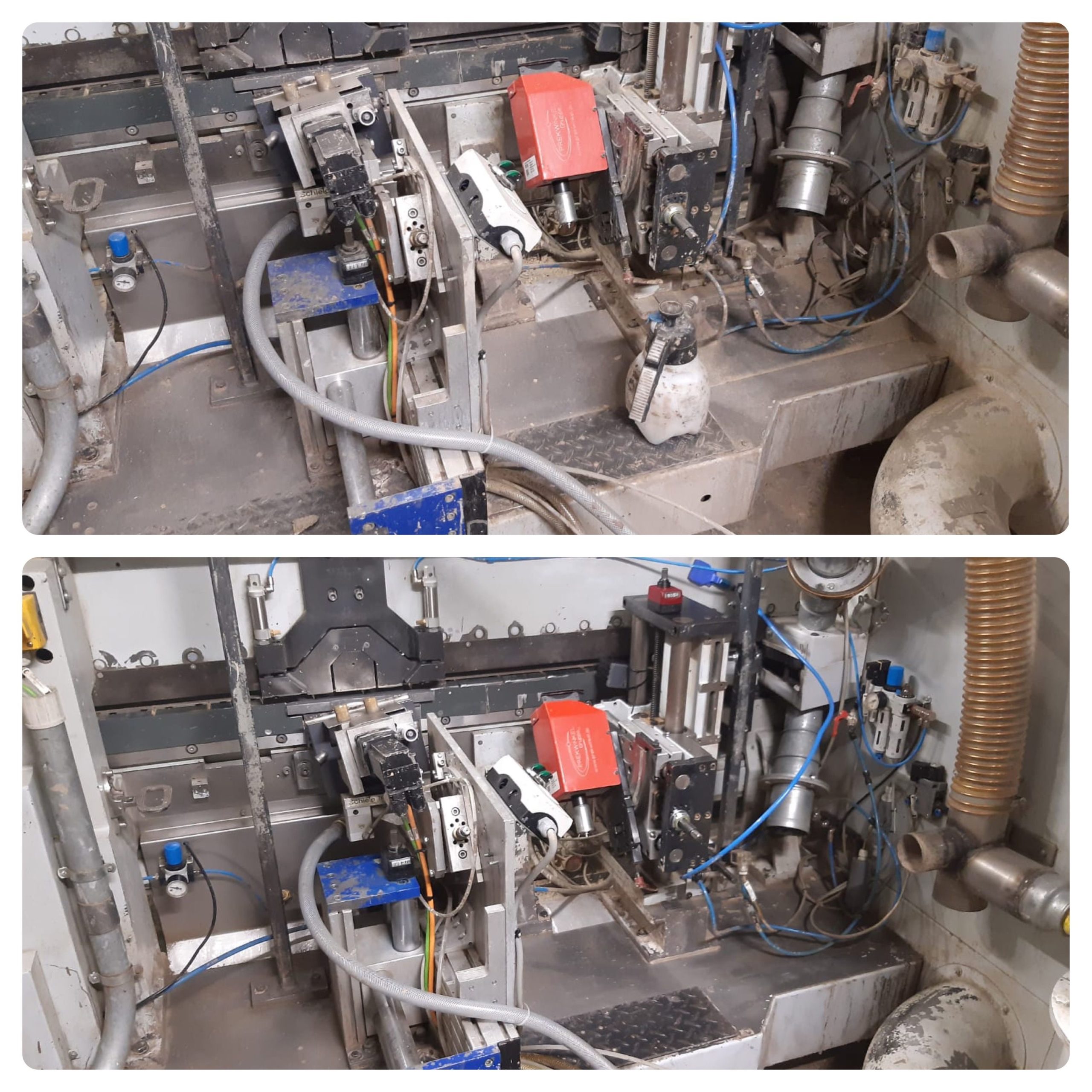

Manufacturing: Snow particulate blasting is used to clean production lines, conveyors, molds, and other manufacturing equipment. It can remove contaminants such as grease, oil, and ink without damaging the machinery.

Aerospace: Snow grit blasting is used to clean aerospace equipment such as engines, landing gear, and electrical components. It is also used for removing coatings and residues from aircraft surfaces.

Printing: Dry ice cleaning is used to clean printing presses and other equipment used in the printing industry. It can remove ink and paper dust without damaging the machinery.

Medical: Snow fragment blasting is used in the medical industry to clean equipment such as surgical instruments, medical devices, and laboratory equipment. It can effectively remove biological contaminants such as blood and tissue.

Overall, any industry that requires precision cleaning and maintenance of equipment and surfaces can benefit from the use of dry ice cleaning.

The time it takes to complete a dry ice cleaning job can vary depending on several factors, such as the size of the surface to be cleaned, the level of contamination, and the complexity of the equipment or machinery being cleaned. However, in general, dry ice cleaning is a faster cleaning method compared to many traditional cleaning methods.

For example, a small to medium-sized production line may take between a few hours to a day to clean using dry ice cleaning, whereas traditional methods such as chemical cleaning may take several days to complete. Additionally, since dry ice cleaning is a dry and non-abrasive method, there is no need to wait for surfaces to dry before use, which can further reduce downtime.

It is important to note that while snow residue blasting is generally a fast cleaning method, it still requires proper planning and preparation to ensure that the job is completed efficiently and safely. A trained professional should assess the cleaning needs and provide a clear estimate of the time it will take to complete the job.

Dry ice blasting can be more expensive than some traditional cleaning methods in the short term, but it often proves to be a cost-effective solution in the long run. The cost of cold jet cleaning can vary depending on factors such as the size of the area to be cleaned, the level of contamination, and the complexity of the equipment or machinery being cleaned.

The cost of Cold cleaning with dry ice is typically higher than that of traditional cleaning methods that use water, chemicals, or solvents. However, there are several factors that contribute to the cost-effectiveness of dry ice cleaning:

Reduced downtime: Dry ice cleaning can often be completed more quickly than traditional cleaning methods, reducing downtime for equipment and machinery. This can result in cost savings by increasing productivity and reducing lost revenue due to downtime.

Extended equipment lifespan: CO2 blasting can be less abrasive than traditional cleaning methods, reducing wear and tear on equipment and machinery. This can result in a longer lifespan for the equipment, reducing the need for costly repairs and replacements.

Reduced waste: Dry ice jetting produces less waste than traditional cleaning methods, such as chemical cleaning or sandblasting, which can result in lower disposal costs.

Improved safety: Solid CO2 cleaning is a non-toxic and non-hazardous cleaning method, reducing the risk of accidents or injury in the workplace. This can result in lower insurance premiums and workers‘ compensation costs.

Overall, while dry ice cleaning may initially have a higher cost than traditional cleaning methods, its efficiency, effectiveness, and reduced environmental impact can result in long-term cost savings. It is important to assess the specific cleaning needs of each situation to determine the most cost-effective cleaning solution.

The frequency of dry ice cleaning for equipment and surfaces can vary depending on several factors, such as the type of industry, the level of contamination, and the cleaning requirements. In general, it is recommended to perform dry ice cleaning on a regular basis to maintain the cleanliness and functionality of equipment and surfaces.

For example, in food processing industries, equipment and surfaces may need to be cleaned daily or weekly to ensure that they meet the required hygiene standards. In manufacturing industries, equipment and machinery may be cleaned on a monthly or quarterly basis to prevent the build-up of debris and contaminants that can affect the production process.

In addition to regular cleaning schedules, it is also important to perform dry ice cleaning as needed based on visual inspections and assessments of the equipment and surfaces. If there are signs of contamination or build-up, such as discoloration or reduced efficiency, then dry ice cleaning may be necessary to restore the equipment or surface to its optimal condition.

It is important to work with a trained professional to determine the appropriate cleaning schedule for your specific equipment and surfaces. They can assess the cleaning needs and provide guidance on the best cleaning frequency to maintain the cleanliness and functionality of your equipment and surfaces.

Yes, dry ice cleaning is an effective method for removing graffiti from a variety of surfaces, including brick, concrete, and metal. It’s also environmentally friendly and doesn’t cause any damage to the surface being cleaned.

Dry ice blasting can be an effective option for removing graffiti from various surfaces, including walls, sidewalks, and other outdoor areas. Graffiti can be challenging to remove using traditional cleaning methods, which may be time-consuming, labor-intensive, and can cause damage to the surface.

Solid CO2 cleaning uses compressed air to blast dry ice pellets at the surface being cleaned, causing the graffiti to disintegrate and detach from the surface. The process is non-abrasive and does not use harsh chemicals, making it a safe and environmentally friendly cleaning option. Dry ice cleaning can also be more efficient than traditional cleaning methods, as it can remove the graffiti more quickly and effectively.

However, the effectiveness of cold cleaning with dry ice for removing graffiti can depend on the type of surface and the age and type of paint used for the graffiti. Some surfaces may be more delicate and require more careful handling during the cleaning process, while older and more stubborn graffiti may require multiple cleaning sessions.

It is important to work with a trained professional to assess the graffiti removal needs and determine if dry ice cleaning is a suitable cleaning option. They can provide guidance on the best cleaning approach and help ensure that the cleaning is performed safely and effectively.

Yes, CO2 pellet cleaning is a great option for cleaning equipment and machinery used in the food industry. The process is completely safe and hygienic and can help prevent contamination and foodborne illnesses.

We hope these FAQs have answered your questions about dry ice cleaning. If you have any additional questions or would like to schedule an appointment, please don’t hesitate to contact us. Our experts are always here to help!

At Dry Ice Danmark APS, we are committed to providing the highest quality CO2 blasting services to our clients. Our team of experts uses cutting-edge technology to remove even the most stubborn contaminants from a variety of surfaces. Whether you need industrial cleaning or a simple car detailing, we’ve got you covered.

So if you’re ready to experience the power of dry ice cleaning, contact us today to schedule your appointment. Our team is standing by to answer your questions and provide you with the best cleaning solution for your needs. Don’t wait, book your appointment today and see the difference for yourself!

available from 10:00 – 19:00

Address: Svanevej 57, DK-4970 Rødbyhavn

E-Mail: info@dry-ice-dk.com